Mechanical face seals, also know as floating seals and duo cone seals, are designed to last in extreme environments to provide superior sealing.

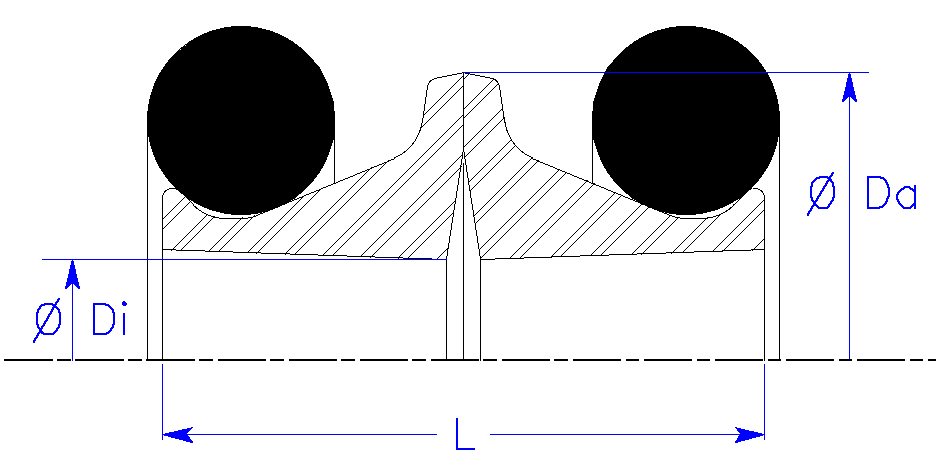

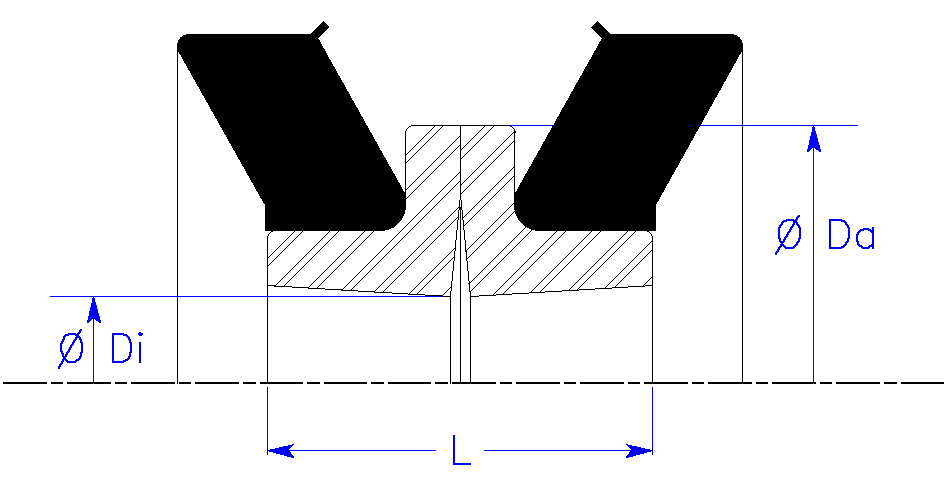

There are two types of mechanical face seals, O-ring and trapezoid types. Both refer to the shape of the secondary sealing element.

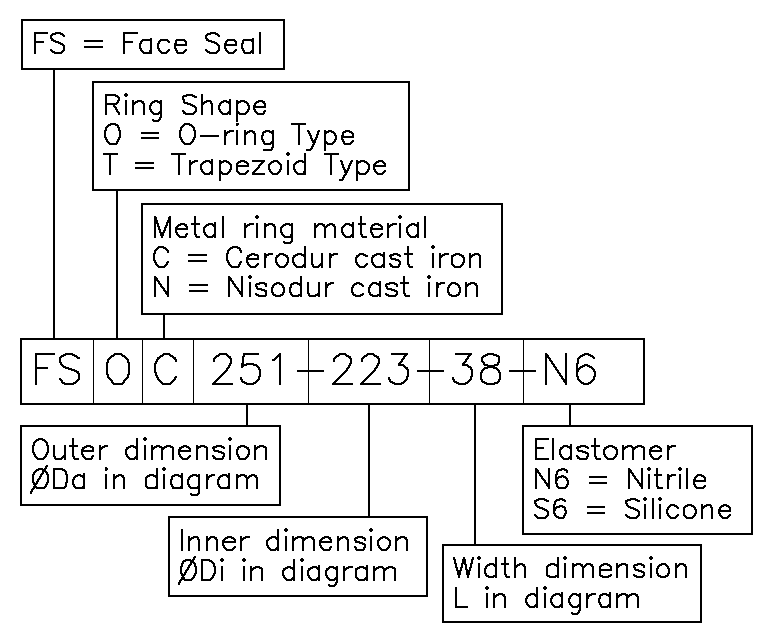

Breakdown of Part Number

Breakdown of Part Number

FS always stands for face seal.

The two different types of face seals are O-ring type (O) and trapezoid type (T). These types refer to the shape of the secondary sealing element cross-section. O-ring type is the most common. The trapezoidal type offers easier installation without special tools, as well as more easily machined housings.

There are two different types of materials used for the internal metal rings: cast iron and bearing steel. The most common material is cast iron. There are two available cast iron alloys: Cerodur (C) & Nisodur (N). Bearing steel is an option when economical considerations are most important. See Mechanical Seal Materials for more information.

The main way to identify these seals is by their dimensions. Our part numbers are organized by the dimensions of the metal inner ring.

Lastly the elastomer the O-ring or trapezoid ring is made of is displayed at the end of the part number. Nitrile NBR rubber is represented by N6; Silicone is represented by S6.