Calculating Actual Seal OD

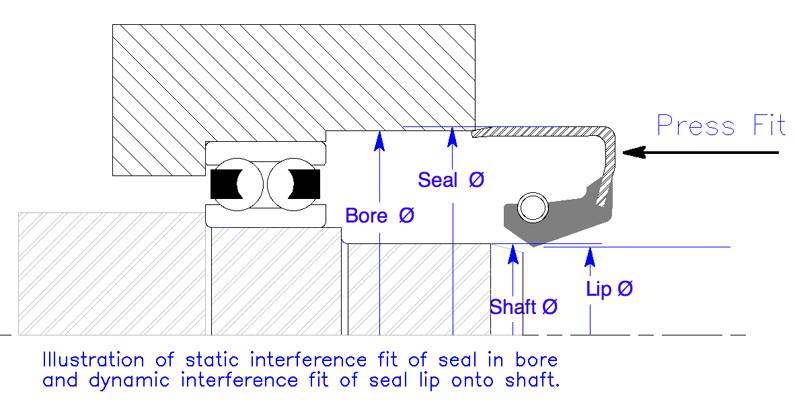

Oversized seal OD allows for static interference fit in bore.

Adding the bore diameter to the press fit allowance will give you the seal OD.

Millimeters |

||||

Housing

|

Metal OD |

Rubber OD |

||

| Min | Max | Min | Max | |

| Up to 50 | +0.10 | +0.20 | +0.15 | +0.30 |

| 50.01-80 | +0.13 | +0.23 | +0.20 | +0.35 |

| 80.01-120 | +0.15 | +0.25 | +0.20 | +0.35 |

| 120.01-180 | +0.20 | +0.28 | +0.25 | +0.45 |

| 180.01-300 | +0.20 | +0.30 | +0.25 | +0.45 |

| 300.01-500 | +0.23 | +0.35 | +0.3 | +0.55 |

Inches |

||||

Housing

|

Metal OD |

Rubber OD |

||

| Min | Max | Min | Max | |

| Up to 2.000 | +0.003 | +0.007 | +0.005 | +0.011 |

| 2.001-3.250 | +0.005 | +0.009 | +0.007 | +0.013 |

| 3.251-4.750 | +0.005 | +0.009 | +0.007 | +0.013 |

| 4.751-7.000 | +0.007 | +0.011 | +0.009 | +0.017 |

| 7.001-11.750 | +0.007 | +0.011 | +0.009 | +0.017 |

| 11.751-20.000 | +0.009 | +0.013 | +0.011 | +0.021 |

Example

SE825-950-57SB

Housing Bore Ø = 9.500″

Metal OD = SB style has a metal OD – See SB

9.507″ minimum seal OD = 9.500″ housing bore Ø + 0.007″ minimum press fit allowance

9.511″ maximum seal OD = 9.500″ housing bore Ø + 0.011″ maximum press fit allowance