There are two ways to identify a seal: by the part number or by its dimensions.

The part number frequently offers the easiest and most error-proof way to identify a seal. You can get the corresponding cross-reference to the Enduro part number in our tables, or in various online tools.

Dimensional:

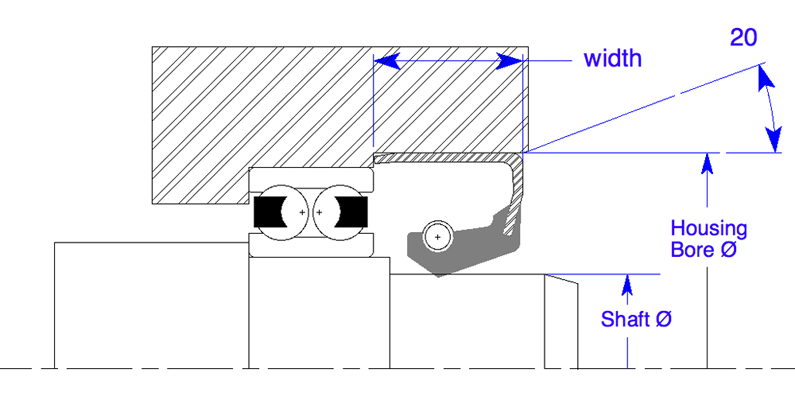

The dimensions of an oil seal consist of three main parts.

Shaft: The dimensions given in the catalogs are for the corresponding shaft, and do not indicate the actual seal inside diameter. The seal inside diameter (lip diameter) is generally smaller than the stated shaft diameter in order to provide a dynamic interference fit between the shaft and the seal lip.

Housing Bore: The dimensions given in the catalogs are not for the seal outer diameter, but for the corresponding housing bore. The seal outer diameter is generally larger than the corresponding bore in order to provide a static interference fit (press fit). This is what holds the seal in place in the bore.

Width: This is fairly straightforward. You have some leeway as seals can be narrower than the bore width. Ideally, as illustrated below, the seal will be stopped against a counter bore. This helps maintain the seal face perpendicular to the shaft.

Enduro Seal part numbers are comprised of a dimensional and style code.

Here is a typical example: SE825-950-57SB

SE = standard oil seal

825 = abbreviation for the shaft diameter, in this case 8.250″

-950 = abbreviation for the housing bore, in this case 9.500″

-57 = abbreviation for the seal width, in this case 0.578″

SB = case style – see SB

No further designation after the SB indicates the default elastomer – NBR70 (see lip materials)